Features

INTRODUCTION

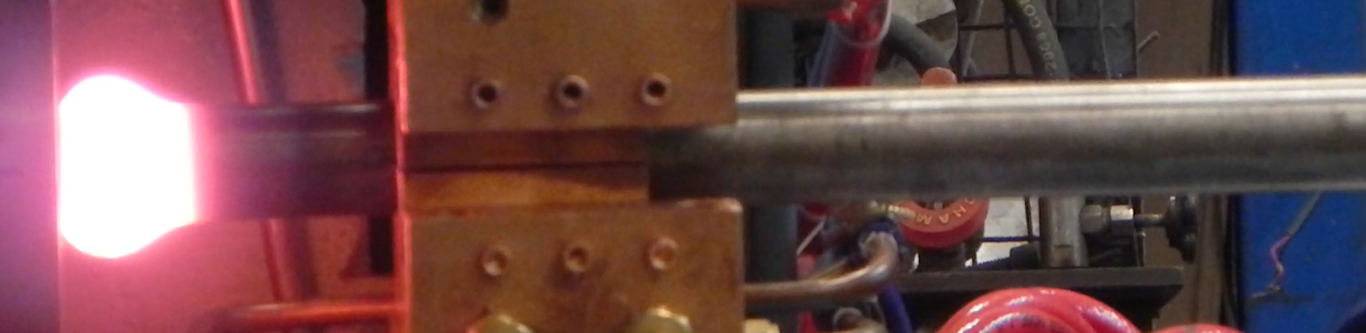

The Electric Resistance Heating is the least expensive way to change electricity into heat in any metallic object. In a furnace, the entire furnace has to be heated, the elements have to be heated, which in-turn many times heat a muffle which in turn heats the part in which heat is desired. Resistance heating is a more direct method of producing heat only in the object in which heat is needed.

Applications

Just a few of the applications would be; wire drawing, extruding, warm or hot heading, brazing, forging, upsetting, roll parts, heat treating, heating strip stock for shearing, for forming, drawing and rolling, soldering and general purpose heating.

TECHNICAL DATA

Following are the specifications

| mary/ Power Supply | MODEL | UNITS | TBH-25 | TBH-50 | TBH-100 | TBH-250 |

| Supply Voltage at 1 ph. 50 Hz | V | 415 | 415 | 415 | 415 | |

| Input power at Max. current | KVA | 25 | 50 | 100 | 250 | |

| Switch fuse | A | 80 | 150 | 300 | 650 | |

| Current taps | No. | 6 | 6 | 8 | 8 | |

| Duty cycle | % | 100 | 100 | 100 | 100 |

ADVANTAGES

- Lower energy consumption.

- Immediate start of heating operation.

- Low scale formation.

- No decarburization of the skin.

- Good soaking of the bars.

- Compact design, smaller outer dimensions.

- No foundations required.

- Shorter heating times with high temperature precision.

- No Pollution